Description

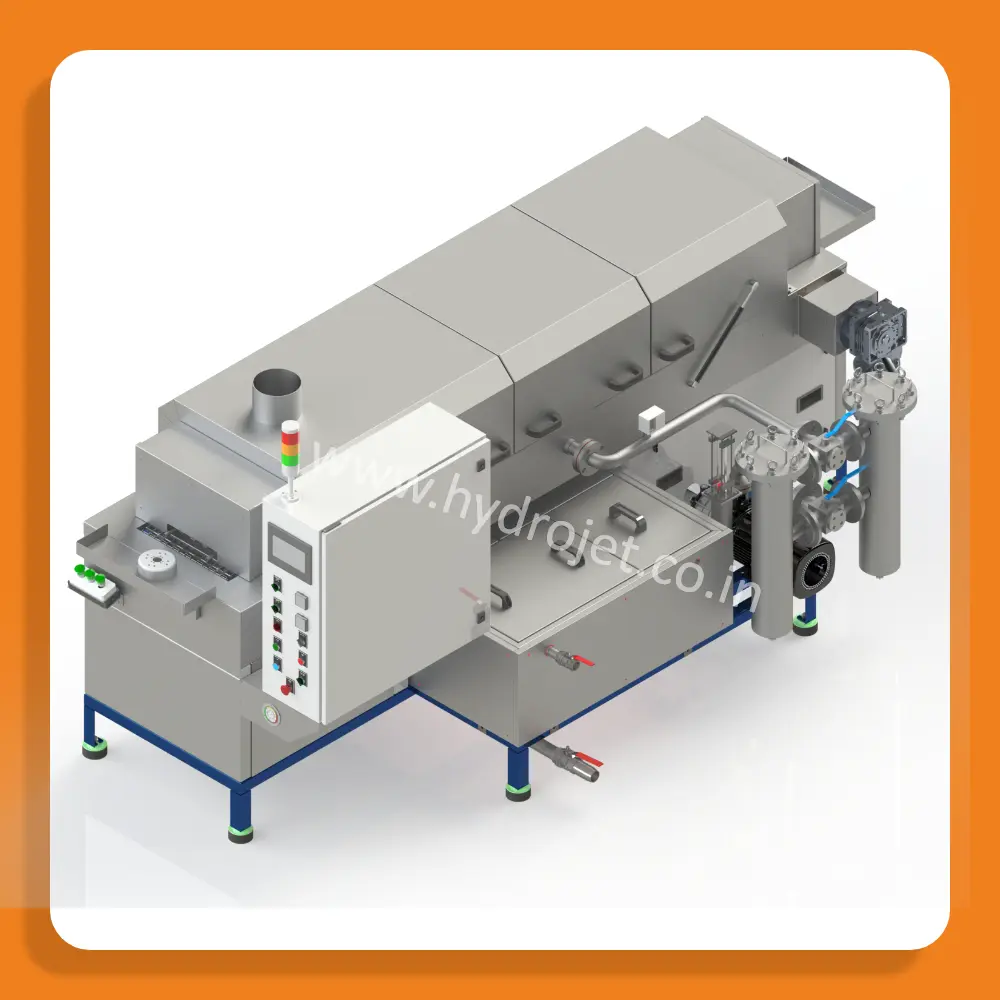

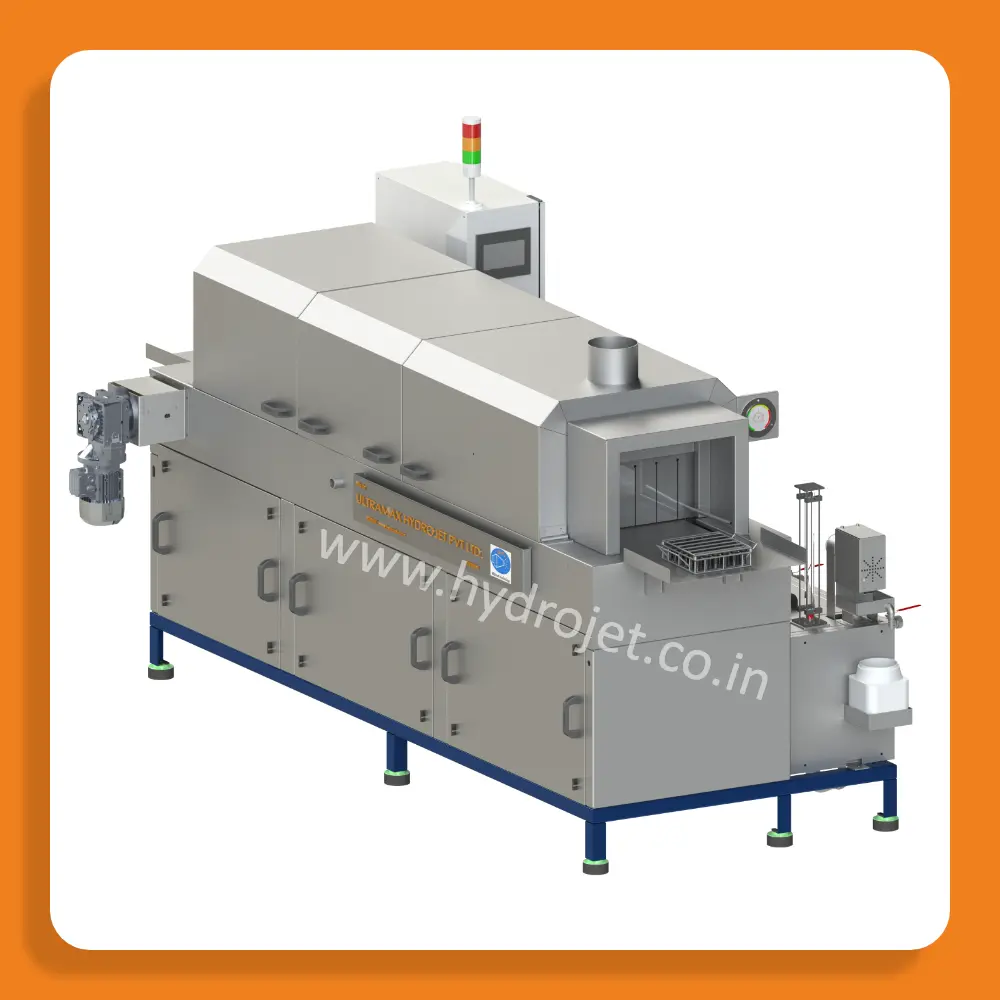

Front Loading Parts Washer works on the principle of Aqueous based clean technology in which the components to be placed in to the component basket either by means of Jib crane (or) EOT crane. The component along with the basket moves automatically in to the Wash chamber and entire cleaning process is automatic.

This Machine works on the principle of Rotary Turntable Mechanism in which cleaning process such as Alkaline spray washing, DM Hot Water Rinsing & Hot Air Blowing will be carried out at single chamber in a sequential Manner. There are various sizes of basket diameter ranging from 720 mm to 2000 mm & Load carrying capacity of Min 500 Kgs to Max 2500 Kgs

Machine Nomenclature

These Machines are commonly known as

Front Loading Component Cleaning & Degreasing Machine

Heavy Component Washer

Front Loading Parts Washer

Engine block Degreasing Machine

Front Loading Industrial Washing Machine

Front Loading Industrial Washer & Dryer

Why Our Machine

We identify the customer cleaning requirements & provide complete solutions on difficult cleaning tasks rather than selling our machines

Innovative design in cleaning Machine towards components & its applications

Discuss on process objectives & determine the cleaning criteria

Achieving the cleanliness level as per Millipore/gravimetric standards with Particle size

Renowned organization in Industrial cleaning Application for more than 2 decades

Manufacturing, Timely delivery & immediate installation

Features

All Wetted parts of the Machine are constructed using stainless steel (SS 304)

The Machine is completely Automated with PLC Logic control

Basket Movement In & out, Door closing & opening & entire cleaning process is Automatic

Washing Lance oscillation Mechanism for Turbo Effect cleaning

Machine is designed & customized specifically as per component cleaning requirements

All safety norms & POKE YOKE has been incorporated in this machine

Designed with Energy efficient standards where optimum level of energy will be used for the cleaning process

Advantages of the Machine

Design as per customer expected cleanliness level & component requirements

Manufacturing & Delivery in a timely manner

The outcome results of the cleaned parts will be in consistency manner

Less Man power fatigue

Running cost per component is minimized

Accessories

Wash Tanks

Electrical Heating Elements

Temperature Controller & sensors

Wash Pump

Oil Skimmer

Tank Level indicator

Recycling Filtration system

Control Panel with PLC Logic control & HMI Display

Automatic Door Open & close

Hot Air blower

Oil Separator

Duplex Filtering system

Safety Light Curtain

Mist Collector/ Fume Exhauster

Paper Band Filtration system

Online Magnetic Separator

Applications

Automotive

Rail & Transit

General Engineering

Re-built workshop

Aerospace